ジェトロ大分

大分県の蔵元紹介 Invitation to Oita Breweries清酒の製造工程 Seisyu (Japanese sake) Making Process

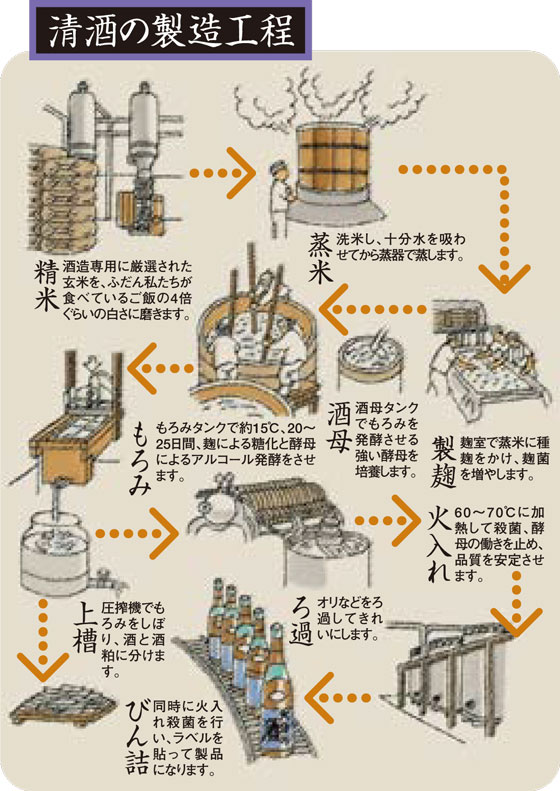

清酒の製造工程

- 精米

(酒造専用に厳選された玄米を、ふだん私たちが食べているお米の4倍ぐらいの白さに磨きます。) - 蒸米

(洗米し、十分水を吸わせてから蒸器で蒸します。) - 製麹

(麹室で蒸米に種麹をかけ、麹菌を増やします。) - 酒母

(酒母タンクでもろみを発酵させる強い酵母を培養します。) - もろみ

(もろみタンクで約15℃、20~25日間、麹による糖化と酵母によるアルコール発酵をさせます。) - 上槽

(圧搾機でもろみをしぼり、酒と酒粕に分けます。) - ろ過

(オリなどをろ過してきれいにします。) - 火入れ

(60~70℃に加熱して殺菌、酵母の働きを止め、品質を安定させます。) - びん詰

(同時に火入れ殺菌を行い、ラベルを貼って製品になります。)

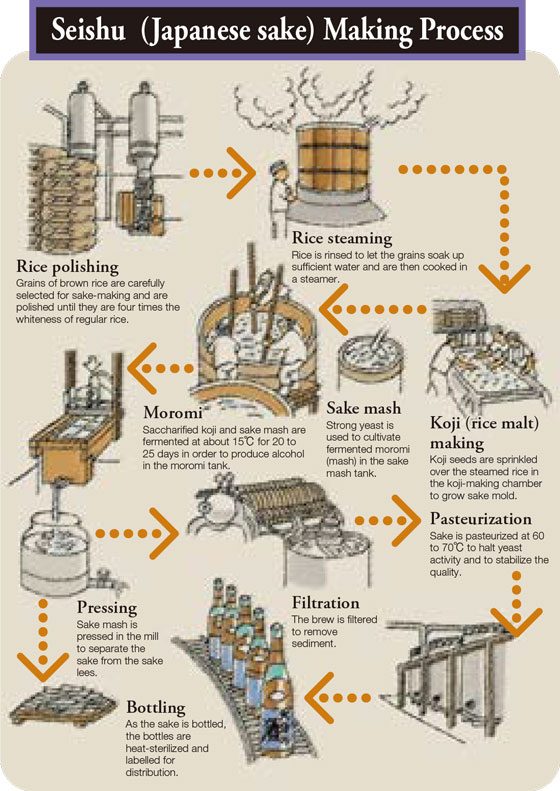

Seishu(Japanese sake) Making Process

- Rice polishing

(Grains of brown rice are carefully selected for sake-making are polished until they are four times the whiteness of regular rice.) - Rice steaming

(Rice is rinsed to let the grains soak up sufficient water and are then cooked in a steamer.) - Koji(rice malt) making

(Koji seeds are sprinkled over the steamed rice in the koji-making chamber to grow sake mold.) - Sake mash

(Strong yeast is used to cultivate fermented moromi(mash) in the sake mash tank.) - Moromi

(Saccharified koji and sake mash are fermented at about 15℃ for 20 to 25 days in order to produce alcohol in the moromi tank.) - Pressing

(Sake mash is pressed in the mill to separate the sake from the sake lees.) - Filtration

(The brew is filtered to remove sediment.) - Pasteurization

(Sake is pasteurized at 60 to 70℃ to halt yeast activity and to stabilize the quality.) - Bottling

(As the sake is bottled, the bottles are heat-sterilized and labelled for distribution.)

大分県酒造組合提供