Meet Japanese Companies with Quality

Printing the Path to Flexible Technology C-INK CO., LTD. IP

Website: C-INK CO., LTD.![]()

Category: Others

Metal nanoink enables the production of inexpensive and flexible circuit boards using conventional inkjet printers

The next generation of electronics is expected to make extensive use of flexible displays and wearable devices that will markedly increase demand for printed electronics. C-INK Co., Ltd. is supporting fast, inexpensive and flexible circuit board production using metal nanoink that can be printed with conventional inkjet printers.

C-INK was founded in 2012 by Masayuki Kanehara. Now company CEO, Kanehara explored the properties of nano-metals as a graduate student at the Japan Advanced Institute of Science and Technology, where his research led him to discover a new process for ink formulation. “Basically, we use the same materials that other companies do, but our concept is completely different,” he says. “We made the ink as close to pure metal as possible. Consequently, our ink is crack-free when it dries, conducts electricity better and has better adhesion properties.”

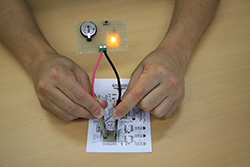

A demonstration of the flow of electricity through a circuit printed on paper with DryCure nanoink.

Printable Solutions

C-INK’s DryCure nanoink is optimized for inkjet printers, and can be used at room temperature under normal atmospheric conditions. The underlying conductive metal ink technology is patented in Japan and the U.S., with patents pending in Europe and China, while Kanehara plans to patent the production and application processes as well.

Available in gold or silver, the ink can even be printed on a standard sheet of paper, becoming a functional electronic circuit when it dries. Kanehara promises that DryCure is compatible with all types of inkjet heads, including piezoelectric and thermal varieties.

DryCure nanoink can be printed with a standard desktop printer.

A Well of Potential

Sales of DryCure began in 2014. Its growing customer base includes Japanese companies making LED signs and panel heaters using DryCure ink circuits, while at least one client uses the ink itself to repair gaps on LCD panel circuit boards.

Kanehara further sees DryCure helping to meet future needs in biosensors, wearable devices and flexible displays. Nevertheless, he adds, “We don’t intend to do this alone – that’s why we’re looking for partners among printed electronics companies to accelerate our development.” In the coming year, the company plans to approach firms in Silicon Valley, with the goal of seeing C-INK adopted for broad industrial use in five years’ time.

C-INK Co., Ltd. produces silver (left) and gold (right) nanoinks, seen here in diluted form.

Printing Outside the Box

Kanehara prides himself on solving problems from the customer’s perspective. “We had many customers that liked the ink and wanted to use it,” he explains. “But they needed to print on plastic film or glass, which an inkjet printer couldn’t accommodate.”

In response, C-INK is now working on its own printer that can print on a variety of materials including paper, glass, film, ceramics and plastic. “This will enable us to offer customers a total solution,“ Kanehara says, adding that he hopes to have it ready as early as November 2016.

With all its innovations, C-INK stands well poised to meet the needs of the next generation of innovative electronics.

Based on interview in October 2016

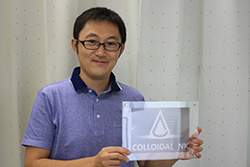

C-INK Co., Ltd. CEO Masayuki Kanehara displays a circuit board printed with the firm's nanoink.

Website: C-INK CO., LTD.![]()