Investing in AI Solutions for Japan's Industrial Robotics Market

Realtime Robotics is an AI solutions company based in Boston, MA with a focus on simplifying industrial robot system development. The company's unique RapidPlan software enables collision-free autonomous motion planning for industrial robots.

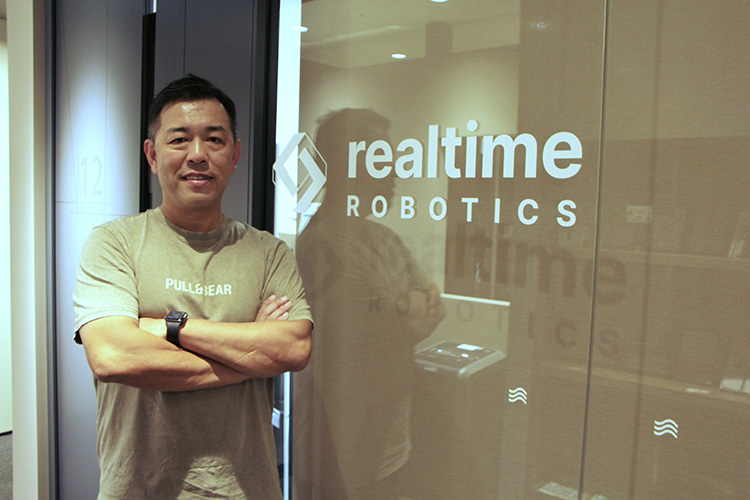

We spoke to Realtime Robotics Japan's Vice President of Business Development Koji Kobayashi about why the company decided to enter the Japanese market, the challenges including technical operations and business culture differences they faced and overcame, and their success in partnering with some of the biggest names in Japan's industrial robotics space.

- Establishment

- 2021/05

- Destination

- Tokyo・Kanto

- Digital & AI

- Semiconductors, Robotics, and Machinery

-

USA

Update : 2025/02

Watch Video

Japan's Dominance in Robotics Creates Opportunities for Innovation

Japan has long been at the forefront of industrial robotics, maintaining its position as a global leader in both development and implementation of robotic solutions. Against the backdrop of a sophisticated manufacturing sector facing growing labor shortages, Japan's reliance on industrial robots has only intensified in recent years. This environment has created unique opportunities for innovative companies looking to enhance automation capabilities, particularly in the area of robot control and optimization.

Koji Kobayashi, Vice President of Business Development,

Realtime Robotics Japan

Introducing Pioneering AI-Based Solutions to Japan

Realtime Robotics' unique RESOLVER and RapidPlan software enables collision-free autonomous motion planning for industrial robots, significantly reducing programming time and improving operational efficiency. This technology addresses a major challenge in manufacturing: the time-consuming process of manually programming robots for complex operations.

The company soon recognized Japan's potential as a key market for its groundbreaking technology: "Japan is a large market with a huge focus on robotics automation due to its severe labor shortage," explains Kobayashi. "Additionally, Japan's laws and codes are very supportive in protecting intellectual property, which made it very attractive for collaboration with Japanese partners."

The decision to enter the Japanese market was driven by several strategic factors, including the country's leading rate of industrial robot usage and the presence of early Japanese investors in Tokyo and Aichi Prefecture.

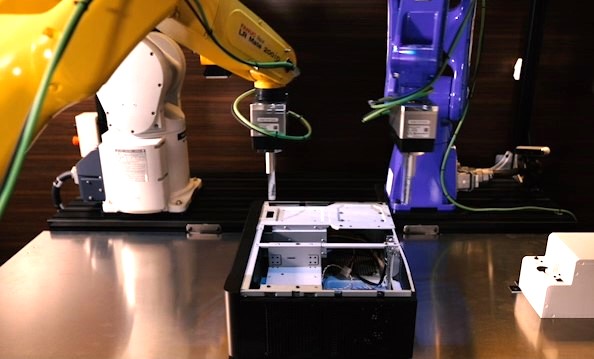

Multiple robot arms move quickly and collision-free, powered by Realtime Robotics' proprietary software

Navigating Market Entry into Japan

Despite the market's potential, Realtime Robotics faced several hurdles when entering Japan. One significant example was the conservative nature of Japanese business culture. "Japanese people generally don't want to be pioneers; they prefer to follow someone else's lead," notes Kobayashi. This cultural preference for proven solutions presented a particular test for a company offering a first-of-its-kind technology.

Staffing the Japanese office also presented issues. As a startup, the company had to overcome concerns about stability and longevity that made it difficult to attract native Japanese talent. This issue, however, led to a novel solution: hiring skilled non-Japanese professionals already established in Japan and familiar with Japanese business culture.

Skilled global professionals well versed in Japanese business culture

Clearing Initial Hurdles Through Valuable Support Systems

The company received support from various sources to overcome these initial challenges. JETRO played a vital role, assisting even before the office's establishment. This support included help with company registration, documentation requirements and eventually, a subsidy project that enhanced both financial resources and business credibility.

The company's existing Japanese investors also proved invaluable, particularly in building relationships and recruiting talent. "We got very good support from our investors in Japan to hire new members in the Tokyo office," Kobayashi explains.

Kobayashi speaks enthusiastically about partnerships with Japan’s leading corporations

Expansion through Strategic Partnerships

Since establishing its Japan office in 2021, Realtime Robotics has achieved remarkable success through a series of strategic partnerships with some of Japan's leading robotics manufacturers. The cornerstone of this success has been its evolving relationship with Mitsubishi Electric, which began in May 2019 and has recently deepened with a significant Series B investment announcement in early 2024.

The Mitsubishi Electric partnership represents a comprehensive integration of technologies and business strategies. The collaboration focuses on incorporating Realtime Robotics' collision-free motion planning technology into Mitsubishi's 3D simulators and factory automation systems. This integration enables the creation of digital twins – virtual replicas of manufacturing processes that optimize efficiency and productivity. Future plans include embedding Realtime's technology directly into factory automation control system devices.

Realtime Robotics' partnership with Kawasaki Heavy Industries has also proven significant, particularly in the automotive sector. This collaboration integrates RapidPlan software with Kawasaki's KRNX open programming platform, enabling real-time control and execution of complex robotic applications. The impact of this integration was on display at Automate 2022, where a demonstration cell featuring two Kawasaki BX100N robots simulated spot welding on a car door, showcasing the system's ability to modify robot motions without reprogramming or manual verification.

The results of these partnerships have been substantial. In automotive manufacturing, for instance, the technology has achieved up to 70% reduction in robot programming time for major manufacturers. The system's ability to automatically generate collision-free motion paths has virtually eliminated the need for time-consuming physical validation of robot movements, leading to optimized work cell footprints, reduced electrical power consumption and lower maintenance costs.

Additional partnerships with industry leaders like FANUC and Yaskawa have further confirmed the broad applicability of Realtime Robotics' solutions across different platforms and manufacturers. The company's technology has been showcased at major industry events, including Automatica 2023 in Munich, where interactive demonstrations highlighted the software's capabilities in logistics, manufacturing and specialized applications like textile handling.

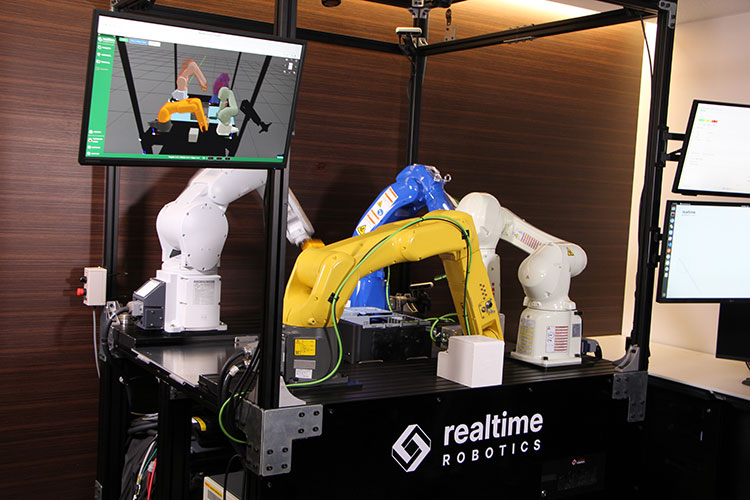

A major factor in accelerating these partnerships was the establishment of a robotics showcase in Tokyo. The demonstration facility, featuring robots from various manufacturers, has proven pivotal in helping potential clients and partners understand the technology's capabilities first hand. "When I started at this company, we only had video presentations," Kobayashi recalls. "After establishing this showcase with robots from different OEMs, everything changed. Every time we welcome somebody from end users like Honda or Toyota, when they see the demo, their face changes. It's a very good opportunity to inspire new use cases."

The showcase demonstrates the technology's effectiveness in assembly and spot welding applications, where multiple robots must operate together in confined spaces. "Spot welding is the most important thing for us," explains Kobayashi, "because many automakers like Honda and Toyota are utilizing bigger robots in very confined places. They are facing many challenges to complete the manual processing right now. We can eliminate such manual processing automatically."

A showcase model demonstrating multiple robots operating together in confined spaces

Future Prospects in Robotics and Beyond

Looking ahead, Realtime Robotics has ambitious plans for expansion in Japan. The company's immediate focus remains on the automotive sector, particularly in applications like spot welding and parts assembly. However, their long-term vision is more expansive: becoming a platform provider for the robotics field.

"We need to be like Google for the robotics field," Kobayashi explains. "It's kind of a platform to control everything, not only robotics but also autonomous mobile robots (AMRs) or humanoid-type robots." This vision includes expanding beyond traditional industrial robots to encompass multiple types of automated systems, creating a unified control platform for the future of automation.

Message to Potential Market Entrants

"When we first got to Japan, we had many, many difficulties," recalls Kobayashi. "For example, we didn't know how to register our company officially; we didn't know anything about the documents or information that needed to be submitted." His experience underscores the importance of seeking proper support and guidance from the outset.

While acknowledging some difficulties, however, Kobayashi emphasizes the opportunities in today's market. "Japan is now very open to any innovation to meet their challenges," he notes, particularly in addressing the country's pressing labor shortage through automation technologies.

The key to success, as demonstrated by Realtime Robotics' journey, lies in a multi-faceted approach: taking advantage of support organizations like JETRO, being open to innovative hiring strategies such as recruiting skilled global professionals and understanding the critical role of physical demonstrations in building business relationships. The company's experience shows that while the Japanese market may present initial hurdles, the potential rewards for innovative solutions that address real industrial needs can be substantial.

For companies willing to invest the time and effort to understand the market's unique characteristics, Japan offers not just a business opportunity, but a chance to be part of solving critical challenges in one of the world's most advanced industrial economies. As Realtime Robotics' success demonstrates, with the right approach and support, international companies can not only enter the Japanese market successfully but thrive and expand, contributing to Japan's ongoing industrial evolution while growing their global presence.

Realtime Robotics Inc.

- URL

Related Success Stories

Regional Information

Explore More

-

Success Stories

Success Stories are based on interviews conducted with foreign companies and foreign-affiliated companies that have successfully come into the Japanese market.

-

JETRO’s Support

We provide consistent one-stop service for establishing a base or expanding business in Japan.

-

Setting up Business

You can find information on overall and detailed steps, cost estimation, an overview of the laws, regulations and procedures related to setting up business, and more.

Contact Us

Investing in and collaborating with Japan

We will do our very best to support your business expansion into and within Japan as well as business collaboration with Japanese companies. Please feel free to contact us via the form below for any inquiries.

Inquiry FormJETRO Worldwide

Our network covers over 50 countries worldwide. You can contact us at one of our local offices near you for consultation.

Worldwide Offices