Meet Japanese Companies with Quality

Lightweight Solar Panel Cleaning Robots Miraikikai, Inc.

Website: Miraikikai, Inc.![]()

Category: Japanese Machinery

A passion for autonomous machines

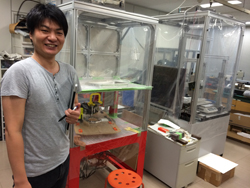

Miraikikai Inc. designs lightweight, battery-powered robots that can autonomously clean large-scale solar panel arrays. Though its head office is in Kurashiki City in Okayama Prefecture, the Miraikikai ("Future Machines") laboratory and research offices are housed in a facility near Kagawa University's Faculty of Engineering. Born and bred in Kagawa Prefecture, company CEO Dr. Tohru Miyake is a graduate of the Faculty of Engineering at Kagawa University and established Miraikikai there while still a student. As a child, Dr. Miyake became interested in machinery and robotics through exposure to his father's packaging factory in Kagawa. While studying at the university's Department of Intelligent Mechanical Systems, he designed a bingo-playing robot that defeated all the competition in the NHK "Robocon" contest.

Exuberant CEO, Dr.Tohru Miyake

Cleaning solar panels in arid areas - without any water at all

Robots to meet remote needs

Solar power is becoming increasingly ubiquitous as the world rethinks its electricity usage, and Dr. Miyake is convinced this trend will continue. Rainwater cleans solar panels well, but in arid desert regions such as Saudi Arabia, dust and sand accumulate on their surfaces due to lack of precipitation, which clogs them up and significantly, curtails electricity generating capacity. Mega solar panel facilities are often located in remote desert areas, with conditions that are too hot for labor-intensive cleaning operations by human workers. To restore panels to full generating capacity, Dr. Miyake developed a robot cleaner with small wheels that utilize state-of-the-art sensor technology to deftly navigate entire solar arrays using rotating brushes to flick away dust and sand.

Small prototypes, big cost savings

The smaller prototype SMR-640AD model, weighing just 17kg, runs on a Li-ion battery cartridge that provides approximately 1.5 hours of usable time per 3-hour battery charge. The robot changes direction to move to the next line of modules when it reaches the edge of the solar PV array, and signals the end of cleaning when it arrives at the "goal" point. On-site engineers need only replace batteries and monitor the progress of the robot as it cleans. Verification tests in the Middle East have shown that in cases of five robots operated by one person, these robots reduce cleaning costs by 80 percent compared with manual cleaning.

Cleaning is uniform and consistent across large solar panel arrays

The robots use brushes to flick away dirt, allowing solar panels to generate power to their utmost capacity

Solar power collaboration opportunities

At the outset, Dr. Miyake envisioned these robots would be used exclusively in countries with high amounts of sunlight and low rainfall. Since the highly successful launch of the prototype model, however, he has received inquires from other nations including Fiji, Chile and also within Japan. Even in regions with heavy rainfall, if panels are flat and not slanted downward, rain cannot provide adequate cleaning. Dr. Miyake predicts that Miraikikai's technology could potentially be adapted to similar robots for inspecting bridges, cleaning large-scale structures and other field applications.

Website: Miraikikai, Inc.![]()