Meet Japanese Companies with Quality

The taming of the screw SAIDA Manufacturing Co. Ltd.

Website: SAIDA Manufacturing Co. Ltd.![]()

Category: Japanese Machinery

- English

- Chinese

Smaller than a grain of sand

At SAIDA Manufacturing, there's a small, tabletop model of a Japanese Zen garden, complete with rocks and a sea of sand raked into patterns. Upon closer inspection of the intricate lines, however, one realizes that these are no mere grains of sand but tiny, intricate metal screws. The company's specialty is machining parts, particularly precision-crafted micro setscrews that are used in numerous products including digital cameras, flutes and even endoscopes.

President and CEO Tomotaka Saida

A tabletop Zen garden with micro setscrews for sand

From machine maker to machine user

The company's founder, Takashi Saida, had been working at another firm designing and selling automatic lathes, a type of metalworking machine. When he left that organization in 1965, he received some machines in lieu of severance pay and decided to use them to make and sell his own parts. Now, almost 50 years later, at SAIDA Manufacturing's present location in western Tokyo, the company has become a worldwide supplier of precision parts despite having only 25 employees.

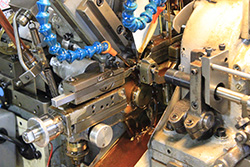

SAIDA Manufacturing modified and modernized their cam-type automatic lathe and also refined their own manufacturing processes and cutting tools to provide a high degree of design and production flexibility. "Since we customized our machines, we have an easier time accommodating the requests of our customers," says the company's current president and CEO, Tomotaka Saida, who took over from his father.

Lower cost, higher speed and better quality

While most mini-screw production facilities have turned to numerical control, Saida prefers his own approach. His self-developed, cam-type automatic lathe strips a small piece of metal with a precision drill bit to produce their specialty DELscrew micro slotted setscrew. Saida's method not only ensures high quality and stability but also includes mechanical separation of the screw from its waste material. More automated production methods tend to output the waste material and setscrews together. Consequently, mechanical production is low-cost and fast: the company's lathes can produce a single setscrew in less than two seconds. And with multiple machines on 24-hour operation, a production rate of up to 400,000 screws per day is possible.

Setscrews are very small-and getting smaller, based on industry trends for today's increasingly compact products. "Fortunately," Saida says, "a shorter length and smaller size is where our production process has its strength." The company is currently making stainless steel or steel-coated setscrews out of zinc to just 1mm in length.

An individual DELscrew micro slotted setscrew

A cam-type automatic lathe

Overseas expansion

SAIDA Manufacturing's expansion overseas largely came about as a result of their Japanese customers moving production to Asia. They have a distributor in Singapore and a sales network that covers Southeast Asia. In 2011, they opened a trading office in Shanghai to support China's growing manufacturing base. Increasing inquiries from abroad are prompting Saida to search for foreign partner companies. But with quality and customer satisfaction at the core of his business, Tomotaka Saida is taking the same careful approach as his company does with setscrews.

Website: SAIDA Manufacturing Co. Ltd.![]()