Meet Japanese Companies with Quality

Precision mold for plastics Sayama

Website: Sayama Mold Manufacturing Co., Ltd.![]()

Category: Japanese Machinery

- English

- German

Famous attention to detail

Japanese craftsmanship is legendary. Throughout the ages, precision, attention to detail, refinement and quality have always been associated with the country's goods. The concept of monozukuri means so much more than its literal translation of "making things." It implies a dedication to a process honed over time, edging as close to perfection as can be. From intricate embroidery on the finest kimonos or carefully created components in electronic goods, this spirit continues to drive the craftsmen of Japan.

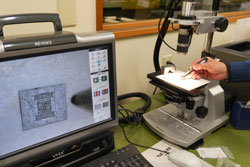

Cutting-edge precision

Embracing the spirit of monozukuri is Sayama Mold Manufacturing Co., Ltd. Located in Iruma City, Saitama Prefecture, the precision manufacturer specializes in making molds and using them to mass-produce plastic and composite components. Its skilled experts can create the most intricate parts-even working on a sub-micron scale. Their output might vary based on the needs of their clients. But you'll undoubtedly have come across some of their work. In fact, if you were to open up just about every smartphone and tablet on the market, at least one component is likely to be from Sayama.

Father and son: President Osamu Oba (left) and Head of Sales Soichiro Oba (right)

Expert craftsmanship meets the latest technology

A passionate family business

At the helm of the 32-strong workforce is President Osamu Oba. Following in his father's footsteps, he strives to capture the spirit and pride of centuries of Japanese craftsmen and instill them in his staff. Under his guidance, the members of his team take the necessary time to finish each mold by hand. That way they ensure every component is as close to perfect as they can make them.

The president's son, Soichiro Oba, helms the sales department. He shares his father's passion and adds to it his extensive experience living and studying in the US. His experiences have inspired him and the company as a whole to innovate and continually improve. Everyone at the company is committed not only to promoting the quality of Japanese engineering, but to keep raising the bar so the country can maintain its edge over ever-improving competition from abroad.

Ever striving to improve

Sayama receives orders from the biggest manufacturers around the world. But rather than just plumping for monetary gain, the president and his son hope to extend their reach beyond automotive and electronics industries into the medical industry. They're targeting new challenges to further improve their skills. And they're constantly downsizing their components to meet the needs of technological manufacturers, as they strive to cram as many features into ever thinner devices.

Precise detail on a microscopic scale

Innovative 0.08mm pitch connector technology has only been developed by Sayama

"As long as there are people, there will be a need to make things for them," says President Osamu Oba. "We want to continue to make the best quality components that make up the tools people use."

Website: Sayama Mold Manufacturing Co., Ltd.![]()