Meet Japanese Companies with Quality

Grinding away at perfection Nogamigiken Co., Ltd.

Website: Nogamigiken Co., Ltd.![]()

Category: Japanese Machinery

- English

- German

Starting small

Nogamigiken had modest beginnings. Founder Shinryo Nogami started his namesake company in 1970 as a one-man operation specializing in grinding-a trade in which he was an experienced veteran. Though small in size (then called Nogami Seiken), it was big on skill and grew from one tiny room in Tokyo to a three-factory facility in Nogami's home prefecture of Ibaraki. More land at a lower cost helped, but unparalleled craftsmanship, know-how and motivation has made Nogamigiken the success it is today. Now led by President and CEO Ryota Nogami, Nogami's eldest son, the company continues its commitment to the technically superior art of manual grinding, which allows for a level of parallel and square precision of 0.0005 mm. With state-of-the-art machines and hand-detailed precision, Nogamigiken is able to offer unrivaled quality in all of the parts it manufactures.

Current President and CEO Ryota Nogami

Manual grinding means higher precision and better results

Taking the lead

Not content to rest on its laurels, Nogamigiken has branched out. While continuing its proud tradition of second-to-none grinding, and bolstered by a supportive educational program for workers, Nogamigiken now covers everything from conceptualizing to designing, testing and producing high-quality instruments crucial to the automobile and electronics industries. Through innovation and precision, Nogamigiken is able to produce superior tools capable of making faultless cuts at an exponentially higher rate than the competition. This level of excellence led it to be named by Japan's Ministry of Economy, Trade and Industry (METI) as one of its "300 Vibrant Craftsmanship SMEs" in 2009. It has also received accolades from the private sector, receiving the "Super Craftsmanship Innovative Parts and Components Grand Prix" in 2011 from the Conference for the Promotion of Monodzukuri and the Nikkan Kogyo Shimbun, the guiding newspaper for the manufacturing industry in Japan. Nogamigiken again received praise from the Nikkan Kogyo Shimbun, which, this time in association with the Resona Foundation, awarded it the "Medium-Small Corporation Excellent New Skill/Product Award" in 2013.

Specialties of the house

Nogamigiken focuses on three main areas: edged tools (for cutting and swaging), precision punches and custom solutions. Forty-plus years of experience, combined with a focus on research and development, have resulted in perfectly smooth, long-lasting edges capable of faultless cuts which leave no burrs-be the material foil, film or electrodes. This translates to a longer part life, more productivity at a higher quality and lower costs thanks to significantly reduced maintenance requirements. The overarching theme is new solutions to daily challenges, and that is exactly what Nogamigiken strives to provide to manufacturers.

Lightweight handheld punches with superior cutting edges leave no burrs

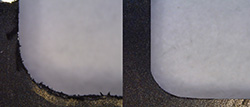

The Nogamigiken difference: close-up of rough edges left by the competition (left); perfectly smooth, burr-free edges with a Nogamigiken punch (right)

Nogamigiken's newest addition to its Ibaraki facility

Forging ahead

Nogami's vision for the future is simple yet ambitious: to be the best in the industry by continuing to create better, more efficient ways to produce precision instruments. This determination to stay at the forefront of machining is motivated by a passion to devise the best instruments, parts and solutions as possible, and a commitment to its founder's method-and art-of manual grinding.

Website: Nogamigiken Co., Ltd.![]()