Meet Japanese Companies with Quality

Precision Prototyping KYOWA INDUSTRIAL CO., LTD IP

Website: KYOWA INDUSTRIAL CO., LTD![]()

Category: Machinery

Kyowa Industrial Co., Ltd., is setting a gold standard as it helps manufacturers develop top-quality working models of their new products.

Quickly building prototypes of new products is a necessary part of the design process for various industries. Because it often requires highly trained staff and specialized equipment, companies tend to outsource it to trusted partners. Kyowa Industrial is one firm that has continuously proved itself to be a reliable company that can deliver high-quality prototypes for industries ranging from automotive and aircraft to LCD makers and medical devices.

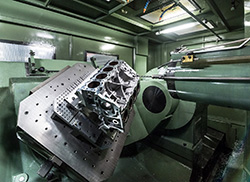

An EV engine head prototype

One sector in which Kyowa Industrial is particularly experienced is the automotive industry. Carmakers might run through dozens of prototypes for body designs or internal components before going to mass production. Kyowa Industrial President Hiroko Suzuki explains that automobile manufacturers will have different prototyping needs, depending on what stage the product is in. It might be when a manufacturer is working on a new idea and trying out a variety of different designs for the car body or the engine, or making a final test version before ramping up the mass production process.

A specialized jig for which Kyowa holds a design patent

Top Gear, and the Talent to Put It Together

A company that specializes in prototyping will need to have production facilities that allow them to create or assemble samples quickly and to manufacturers' specifications. Kyowa holds a design patent for a specialized jig that gives the company an edge in quickly and accurately making prototypes. In addition they have specialized machines such as a five-axis machining center, which gives them the unique capability to efficiently produce engine cylinder blocks.

Equipment is important, Suzuki says, but it is only as good as the human engineers who can execute designs under time pressure and changing priorities: “In order to be able to produce limited runs of highly advanced products, we need highly skillful engineers who are creative, fast and not afraid of trying new things – even if that means taking risks. We need to have a flexible mindset as we cannot plan for the many changes in requirements each new project brings.”

Kyowa counts major Japanese automakers among its clients, and they have worked with these companies on everything from motor case prototyping for electric vehicles to development on their F1 race cars – a process that Suzuki says demands “the utmost in problem-solving skills and flexibility.” In addition to their clients' recognition of their technical acumen, these two competitors trust Kyowa to keep their secrets intact.

Prototypes for Future Development

Suzuki wants to further build on Kyowa's extensive experience in prototyping in Japan to expand their business in US markets, particularly the auto industry. In 2015, they opened their first satellite office to help them meet that target.

The firm is also looking to deepen its strength in prototyping for the LCD, semiconductor, aviation, and medical device industries. For this latter product space, Suzuki says that the comparatively open US business environment offers a wealth of opportunities.

Hiroko Suzuki, president of KYOWA INDUSTRIAL CO., LTD

With an eye on the next stage of her company's global business development, Suzuki is reminded of the lessons Kyowa learned in preparing for Formula 1 races: “Our teams needed to work very hard over many sleepless nights to accommodate competitors' last minute changes in design. Thanks to this experience we are sure we can handle any client in the world!”

Based on interview in December 2015

Website: KYOWA INDUSTRIAL CO., LTD![]()