Meet Japanese Companies with Quality

Simple technologies that could change the world FUJIKIHAN CO.,LTD.

Website: FUJIKIHAN CO.,LTD.![]()

Category: Japanese Machinery

A constant drive toward increased efficiency

Given Japan's historical disadvantage with regards to natural resources and its traditional reverence for nature, the country has been at the forefront of creating industrial developments that are both efficient and environmentally friendly. This drive for increased efficiency led to the Wonder Process Craft (WPC), as it was dubbed by Japan's automakers, developed by Fujikihan Co. Ltd.

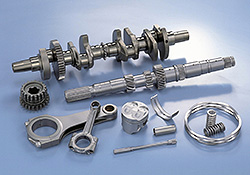

WPC is a surface-modification technique that involves bombarding a metal surface with extremely small particles. By repeating the process of rapidly heating and cooling, the application of high compressive residual stress with a peak near the surface, generation of the microstructure, improvement of the surface's hardness, and the fabrication of the micro dimple surface becomes possible to modify. This leads to high strength and tenacity, and also improves fatigue strength and frictional characteristics. The practical benefits are that WPC-treated components last between five and 10 times longer than untreated components. In engine parts, the lower friction due to the improvement of fatigue strength means less energy is required for movement. Japanese automakers that use the process have seen a drop in consumption from 17-18 km/l to about 22-23 km/l in some models. The WPC process itself is simple and scalable. It can be done by hand, as Fujikihan still does at their factory, or it can be completely automated in robotic assembly lines for mass production.

Fujikihan President Yoshio Miyasaka

WPC-treated engine components

Based in Aichi Prefecture, Fujikihan holds 48 of the patent related to WPC processing in Japan, and also in the U.S., the European Union, China, Korea, Taiwan and Hong Kong. Fujikihan has licensed the process to over 140 companies that use it both locally and internationally.

Innovation results in a breakthrough

Fujkihan's continued development of its WPC technology led to the discovery of powder impact plating, or PIP, treatment. Titanium powder is sprayed with compressed air, and the heat formed when it contacts the object through collision by high speed injection creates a titanium oxide film that adheres without the need for molten titanium to help bind it. The process leads to the formation of an oxygen-depleted layer toward the bottom of the film. Through testing, Fujikihan found that this layer binds to the small amounts of oxides present in various impurities, which, through electron transfer, reduces oxidation and thus impurity from its surroundings. The ease of production, low cost and ability to be used in any environmental condition make it an unprecedented leap forward in catalyst technologies.

PIP Titanium High Efficiency Natural Catalyst

A one-stop solution to many of the world's problems

The PIP Titanium High Efficiency Natural Catalyst has been an extensively tested in-house as well as by major automotive and medical companies and educational institute. It purifies water, deodorizes the air and has antibiotic properties. Its most impressive property, however, is the purification of fuel. In tests run by automotive and engine manufacturers around the world, simply placing the product into a fuel tank removes impurities from the fuel, improving its combustibility and thus reducing consumption and carbon emissions. In some tests, a 17-20 percent increase in range and reduction in CO2 have been measured.

The factory floor at Fujikihan Co. Ltd.

Challenging established practices

The PIP Titanium High Efficiency Natural Catalyst is the cheap and simple technology the world has been searching for to reduce the global carbon footprint. Sadly, however, the majority of big players in the industries that could be transformed by this technology are governed by attitudes that place more emphasis on their bottom line than climate change. Many companies refuse to license the technology simply because they didn't develop it themselves, despite their own tests showing how effective it is. As a result, areas where the PIP Natural Catalyst could be most beneficial to society are being closed off by the very business practices that caused the climate crisis.

Website: FUJIKIHAN CO.,LTD.![]()