Meet Japanese Companies with Quality

Metal tube E.S.Q. Ltd.

Website: E.S.Q. Ltd.![]()

Category: Japanese Machinery

Autos, aerospace and endoscopes

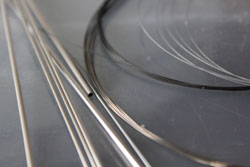

"We are inspired to achieve what others say they can't do," says Nobuyuki Takabatake, president and CEO of E.S.Q. Ltd., in summarizing his company's approach to micro metal tube production. Applications of micro metal tubing are wide-ranging, but E.S.Q.'s notable success stories include manufacturing parts for the anti-lock braking system in German luxury automobiles, engineering structural tubing for an aerospace defense contractor that is the largest company in the U.S. and making endoscope parts for Japanese big enterprise.

E.S.Q. Ltd. President and CEO Nobuyuki Takabatake

E.S.Q.'s micro metal tubing is used in aerospace, auto parts, electronic components, medical devices, nuclear power plants and even submarines

Experience from TV tubing

Takabatake has extensive experience in metal tubing. He previously worked as a technical manager for an electronic components manufacturer, overseeing the design and construction of metal tubes for cathode ray guns in television sets. The overwhelming shift to TVs using liquid crystal displays and other flat screen technology did away with that business, but Takabatake was certain he wanted to continue working in metal tubing.

He left in 2000 and started E.S.Q. with three of his former coworkers, basing their name on the core concepts of "Environmentally friendly," "Specialty" and "Quality manufacturing," and it has grown steadily since. The company now supports diverse concerns including the aerospace, auto part, electronic component, medical device, nuclear power plant and even submarine industries.

Products are the sales force

"There aren't many companies around the world making and selling many types of thin tubing with a small number of lots like ours," says Takabatake. His company excels not only in making ultra small tubes from a wide variety of rare metals but also in doing its utmost to satisfy specific customer requests for them, whether they concern thinness (or thickness), heat resistance, flexibility, functionality or sophisticated craftsmanship. The result is that E.S.Q. products are so good they nearly sell themselves. Takabatake handles most of the sales responsibilities himself but adds: "Our products are the real sales force."

E.S.Q. relies on the superior skill of its 22-member staff to develop micro tubing that cannot be made elsewhere

Cutting-edge metal tech

The equipment E.S.Q. uses to craft micro metal tubing is surprisingly orthodox. While other companies are turning to automation, E.S.Q. is going in the opposite direction, relying on the superior skill of its 22-member staff to develop micro tubing that cannot be crafted elsewhere. Takabatake recalls with pride one customer who sought tubes with 22-micrometer thinner walls made from the rare metal tantalum. E.S.Q. consulted with a university professor who determined that such thinness would exceed the limits of tantalum at the crystalline structure level. Nevertheless, E.S.Q. refused to give up and succeeded in creating the ultra-thin tubing-much to the professor's astonishment.

E.S.Q. goes to great lengths to fulfill customer requests-they once produced 20-meter long micro tubing using a special alloy when the customer could only find 50-centimeter sizes elsewhere

Medical expansion

In 2011, the company started exhibiting overseas at events such as MEDICA in Dusseldorf, Germany, which bills itself as the world's largest medical trade fair, and MD&M WEST in Anaheim, USA, which is the world's largest medical OEM event. Customers of E.S.Q. now span 13 countries and Takabatake hopes to increase that number, especially as he seeks to double his medical device business. With superior technology and a clear commitment to meeting client needs, it's obvious these aren't pipe dreams.

Website: E.S.Q. Ltd.![]()