JETRO Global Connection -Accelerate Innovation with Japan-

Interview

Going Global with Small-Scale Ammonia Production

(Japan)

Mar 15, 2023

This article features Tsubame BHB, a startup in the chemical science field with a big vision to change agriculture around the world. The startup was established based on electride catalyst technology developed by Hideo Hosono, Professor Emeritus at the Tokyo Institute of Technology (Tokyo Tech). Thank you to our interviewees, Koji Nakamura, Director, and Executive Officer.

Could you explain the company's beginning and your product?

Professor Hosono had been working on high-performance semiconductors. When talking with a colleague, he realized this research could lead to some improvements, but it was not essential to life. He began thinking about how he could contribute to the basic needs of all people, like food and shelter. Choosing the topic of food, he focused his research on ammonia and the Haber-Bosch process, a method developed in 1913 in Germany.

He presented a new innovative ammonia synthesis in 2012. The professor wrote a paper about it, and he is a famous professor worldwide because he has been one of the Nobel Prize candidates. He realized the synthesis of electride![]() (material containing electrons inside) for the first time in the world by using a cheap cement material.

(material containing electrons inside) for the first time in the world by using a cheap cement material.

After that, Tsubame BHB![]() was formed in 2017. We started the business with decentralized ammonia production as a small compact-size ammonia production system. Developing ammonia production that is small-scale and efficient is important because it is one of the main chemical components for fertilizer and is essential for agriculture around the world.

was formed in 2017. We started the business with decentralized ammonia production as a small compact-size ammonia production system. Developing ammonia production that is small-scale and efficient is important because it is one of the main chemical components for fertilizer and is essential for agriculture around the world.

The base technology is a catalyst with low temperature and low-pressure synthesis compared to the conventional process. With the method developed by Professor Hosono, we penetrated the smaller market with our technology, while our conventional method is used at very large sites. Our technology is relatively small and can be a low investment of around $10 million.

Company Pilot Plant (Photo provided by Tsubame BHB)

Are you targeting the food and agriculture industries with this product?

The largest segment of ammonia use is agriculture, at about 80 or 85%. It's also used in the chemical industry. As a new application, Japanese companies are focusing on decarbonization, and they utilize ammonia as a CO2-free fuel.

It can also be used for nitrogen fertilizer without CO2 emissions. It's beneficial for countries that don't have many resources for fertilizer. Our concept is small-scale distributed ammonia production. Even in a country where it is difficult to produce ammonia, they can start to produce ammonia with this technology. It can be used in countries with different natural resources and different climates. With this technology, any country can be rich, even if they are not rich in natural resources.

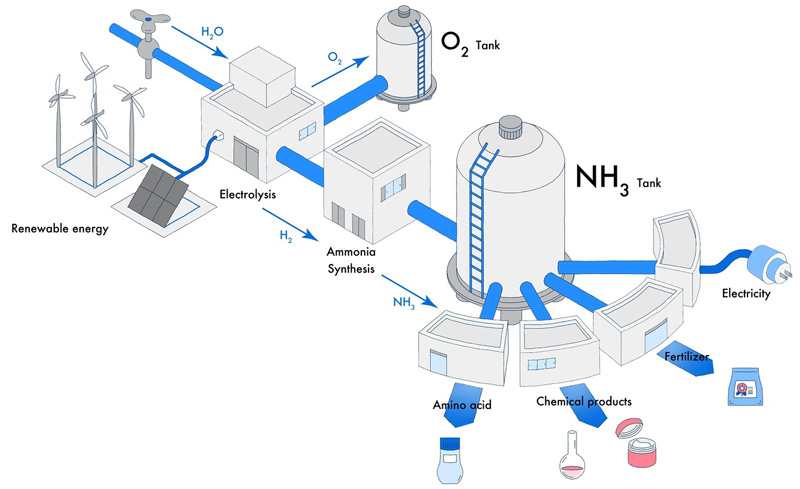

Process Diagram (Image provided by Tsubame BHB)

Are there any challenges that you've faced as a startup?

We have about 60 employees, but the global market is quite large. To expand our business, we must build a network with international partners. We would like to focus on operations and technology development, but at this stage, we also need to focus on growing our network.

One of our partnerships is developing an inorganic membrane with Mitsubishi Chemical, Japan's largest chemical company. We use this membrane with our innovative ammonia process. Under the current conditions, our process is a complex process, like recycling. By utilizing the Mitsubishi Chemical membrane, we can make this process simple. This collaboration is one example of how we've made connections with a Japanese company.

Are you planning to expand to other regions or countries?

Our targets are the US, Canada, India, and Chile because it has a large market for renewable energy. It's very competitive. We are also interested in Thailand, Laos, and Southeast Asia. Small-scale ammonia production can open up a lot of possibilities because it can change the structure of the fertilizer supply chain, cutting down on transportation and storage costs. We also need to connect with industries like new energy and green ammonia.

Can your technology be used with different methods used in Asia and North America to produce nitrogen?

In the North American market, producers use ammonia as a fertilizer, then insert anhydrous ammonia into the soil. So, there is no need to produce nitrogen fertilizer. The project owner can produce green hydrogen and ammonia, then distribute them to farmers. But countries like Japan, Thailand, and Laos don't use anhydrous ammonia.

In Japan or Southeast Asia, there are nitrogen ammonia derivatives, such as ammonium sulfate or ammonium phosphate. Those kinds of derivatives will be granulated and sold in the market. In that case, we need another plant for derivatives downstream from our ammonia plant. That is a bit complicated, which is why the US market is much simpler. It’s one of the reasons we are more interested in the US market. Also, the US now has a subsidy for green hydrogen. It's one of the best subsidies for it in the world.

Where would you like to see the business in five years?

We plan to hire personnel in each field of engineering and public relations to raise awareness worldwide. We also want to involve large corporations and connect with them in joint developments. Right now, we are discussing joint developments with a few overseas corporations. Tsubame BHB has about 60 employees, but the market is global. There isn’t a base overseas yet, so we would like to partner with more manufacturers and businesses in different parts of the world.

What are your recommendations for startups working with JETRO?

There are many JETRO branches, and each country's regulations differ. We get advice on each country’s culture, local regulations, visa applications, and the hydrogen market. Startups can rely on JETRO's advice in each country because they don't know each area.

Mr. Koji Nakamura (Photo provided by JETRO)

- Profile of Koji Nakamura, Director and Executive Officer

- Nakamura joined Toyota Tsusho Corporation and was seconded as an engineer of organic materials to material engineering divisions of Toyota Motor Corporation and its coordinating company for ASEAN, Toyota Motor Asia Pacific Engineering & Manufacturing Co., Ltd. He contributed to reducing Toyota Motor’s costs by auditing the processes of suppliers and evaluating local materials in the ASEAN and India region, and he led his team in earning a “superior” award from Toyota Global for cost reduction. At Toyota Tsusho Corporation, he established new projects, gained new customers, and traded internationally. In 2017, He joined Universal Materials Incubator Co., Ltd., a venture capital firm. Starting in April 2019, he has been involved in Tsubame BHB Co., Ltd., an investee he is responsible for. He graduated from the Applied Chemistry Department at the Nagoya Institute of Technology and completed a program at the Graduate School of Commerce at the Waseda University. He has a master’s degree in business administration (MBA).

- Report by:

- UEDA Momoka, Innovation Promotion Division, JETRO

- Report by:

- KAGA Yusuke, Innovation Promotion Division, JETRO

-

Techstars is bringing its world-renowned accelerator to Tokyo

April 2024

-

The Innovative Collaboration Bringing Kyoto’s Zen Wisdom into the Virtual World

April 2024

-

Caster’s is reinventing Remote Work and aiding Startups in Japan and Germany

March 2024

-

Spatial Pleasure, the Japanese startup aiming to use data to makes cities more sustainable

March 2024

-

How SMTB hopes to build regional startup ecosystems across Japan

February 2024

-

Navigating the Frontiers of AI in Manufacturing with Hutzper

February 2024

-

MatchHat is building a one-of-a-kind platform for creatives globally to connect and collaborate

February 2024

-

How the Japanese startup Archelis is removing strain from standing work

January 2024